The other machining processes

To ensure a complete product with all the machining processes (a condition required for the company's competitive edge on the market), we have always been equipped to perform deburring through barrel finishing and sandblasting and recently with the innovative TEM technology (thermal deburring).

There are also machines for mechanical processing in general like workstations and transfer machines.

Mechanical construction / secondary mechanical

processing department

Builds and assembles about 60 pieces of equipment a year including die-casting moulds, machining equipment and burr-shearing equipment, as well as providing maintenance on the more than 1,000 units we already have.

NUOVA FRAMAR recently launched a complementary business involving secondary mechanical processing on aluminium and zamak die-cast parts.

Barrel finishing and riser removing department

With a barrel finishing department we can complete the process up to the deburring of the pieces. Four automatic discharge burring machines smooth and deburr small pieces. Thanks to the many expert suppliers in neighbouring areas and beyond, we are a strategic partner in a network of companies, providing complementary machining processes to make finished products.

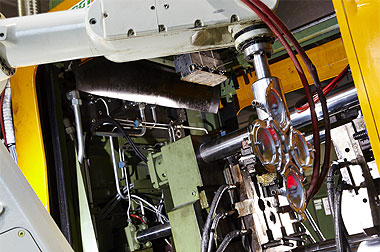

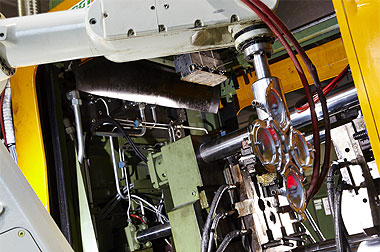

ON LINE SHEARING MACHINE

Islands with ad-hoc design featuring a robot with 6 axes, on line shearing machines, laser control and automatic evacuating machines deliver perfect pieces ready to be packed.

Electroplating and surface treatment

With a production chain, consisting of highly reliable and for years certified partners; we are able to guarantee to finish the products with a variety of processing steps even after the casting process.

We are capable to perform any desired type of treatment on each kind of surface.

Grinding, polishing, polishing by vibration, Chromium (as chromium AUDI 3Q7, chrome "Silver Shadow" for Daimler AG, Mercedes) to the most complex and diverse galvanic surfaces, are only some of the desired and most common types of treatment.

Go back to production

There are also machines for mechanical processing in general like workstations and transfer machines.

Mechanical construction / secondary mechanical

processing department

Builds and assembles about 60 pieces of equipment a year including die-casting moulds, machining equipment and burr-shearing equipment, as well as providing maintenance on the more than 1,000 units we already have.

NUOVA FRAMAR recently launched a complementary business involving secondary mechanical processing on aluminium and zamak die-cast parts.

Barrel finishing and riser removing department

With a barrel finishing department we can complete the process up to the deburring of the pieces. Four automatic discharge burring machines smooth and deburr small pieces. Thanks to the many expert suppliers in neighbouring areas and beyond, we are a strategic partner in a network of companies, providing complementary machining processes to make finished products.

ON LINE SHEARING MACHINE

Islands with ad-hoc design featuring a robot with 6 axes, on line shearing machines, laser control and automatic evacuating machines deliver perfect pieces ready to be packed.

Electroplating and surface treatment

With a production chain, consisting of highly reliable and for years certified partners; we are able to guarantee to finish the products with a variety of processing steps even after the casting process.

We are capable to perform any desired type of treatment on each kind of surface.

Grinding, polishing, polishing by vibration, Chromium (as chromium AUDI 3Q7, chrome "Silver Shadow" for Daimler AG, Mercedes) to the most complex and diverse galvanic surfaces, are only some of the desired and most common types of treatment.

Go back to production

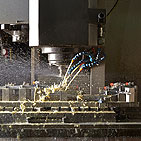

Rolling stock

- micron hsm 600 high speed vertical processing centre

Automatic tool change

Tool path 600x600x800 - Alcor universal milling machine

Tool path 1500 x 800 x 600 - tos mc100v vertical processing centre

Automatic tool change

Tool path 200 x 800 x 600 - CNC lathes

- Grinders

- Electro erosion machines

- Threading equipment