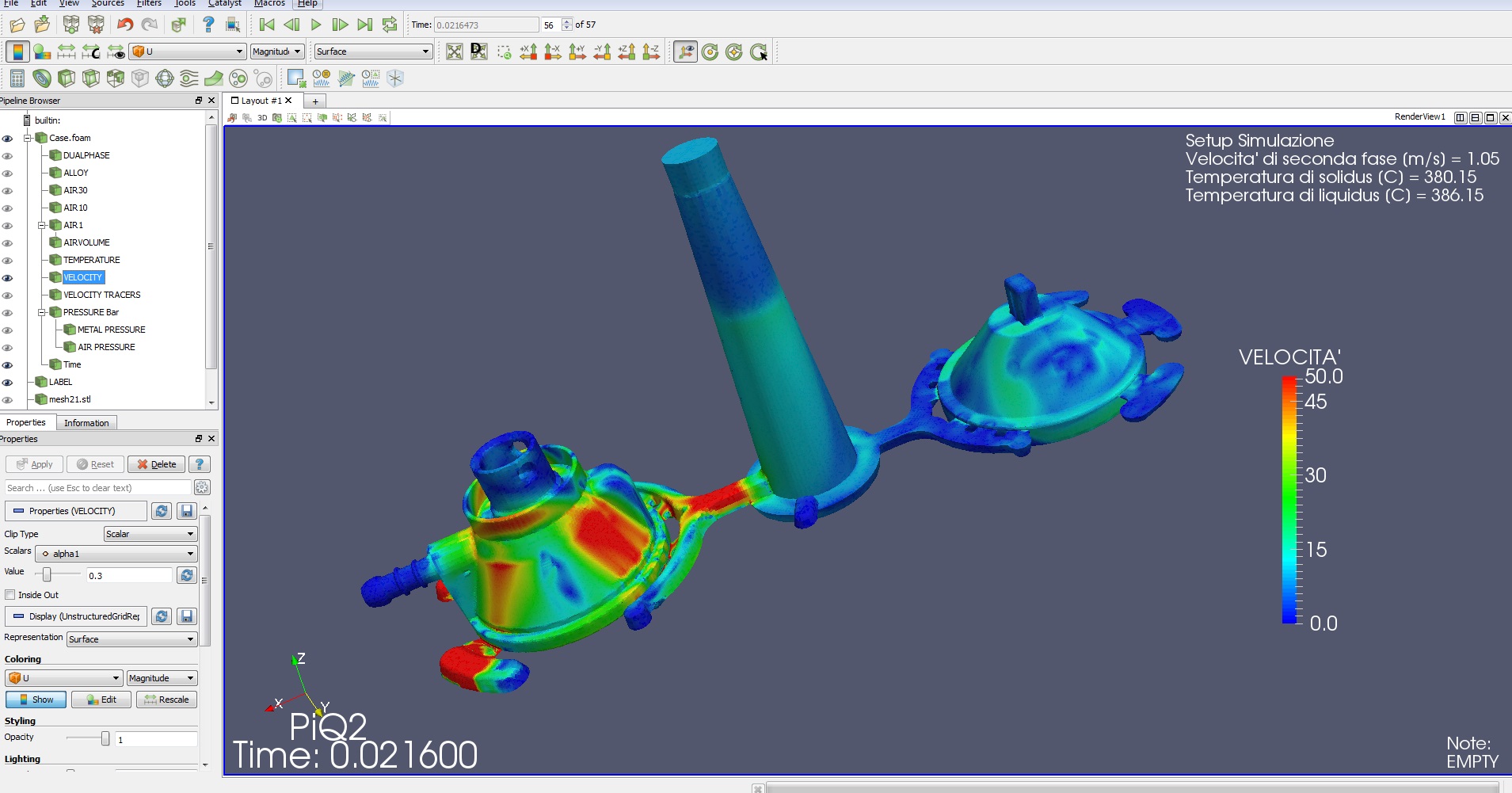

SIMULATION SOFTWARE CASTLE

05 May 2016Nuova Framar has a complete knowledge of the behavior of the die-casting process, even before producing and before the realization of the equipment, which permits a considerable saving in terms of time and costs, by checking in advance the criticality of the mould design, process temperature and optimal tonnage of the press.

Thanks to the use of the Castle simulation software, a modern application of thermo-fluid-dynamic modeling, which shows in real-time the liquid and gaseous phase to simulate the casting process from the injection to the solidification. This ability permits to forecast and to guarantee obtaining final products without casting defects for end customer, at the best cost.

The Castle suite is able to accompany the toolmaker and foundry through all phases of design coming to the simulation of the flow, which allows evaluating in advance the critical issues of the mould and permits to make necessary improvements and/or corrections. Castle is the innovative solution chosen by Nuova Framar, presenting advanced mathematical concepts in an interface designed to make it to an extreme simple and intuitive software.

The advantage of the software used by Nuova Framar is due to the use of mathematical rules derived from the principles of fluid dynamics and experience in melting and moulding processes. All information are used to evaluate and integrate the theoretical formulas, while the results of the calculations are expressed in understandable and interpretable in an easy way for all employees without a specific technical background.

The software applied by Nuova Framar is able to give specific suggestions, for example to improve the quality of the injection, the necessity to use a larger piston, modify the alloy, the temperature or change the mould configuration. All these suggestions are expressed according to all those who are active in the zinc die casting operations or also in numbers or formulas.

News