The company

NUOVA FRAMAR has been operating in the zinc alloy (ZAMAK) die-casting field and making die-casting moulds since 1969. Initially created to manufacture clothing and footwear accessories, over the years the company has evolved, based on market needs, and now specialises in all sectors, in mostly technical fields.

By using 1,500 tonnes/year of zamak, NUOVA FRAMAR is one of the most complete and well-equipped companies in terms of manufacturing zinc alloy items. The plant covers 7,000 sq m, 3,000 of which are covered, and employs about 30 employees in three manufacturing departments, working two shifts. There are considerable allied activities, involving a number of companies in neighbouring areas and beyond, providing NUOVA FRAMAR with the ideal support to ensure clients with an impeccable service from A to Z. We provide semi-finished and finished pieces with a number of surface treatments and/or machining processes in general. Our in-house mechanical construction department has a fundamental role and ensures fast routine maintenance for the more than 1,000 pieces of equipment we have in stock.

More than 50% of the turnover comes from EU countries, which allows us to consolidate a structure whose quality level is ensured by one of the world's top certification bodies. NUOVA FRAMAR is an ideal, flexible partner that can meet the highest technical/quality requirements of every product whilst ensuring an optimal price/quality ratio.

By using 1,500 tonnes/year of zamak, NUOVA FRAMAR is one of the most complete and well-equipped companies in terms of manufacturing zinc alloy items. The plant covers 7,000 sq m, 3,000 of which are covered, and employs about 30 employees in three manufacturing departments, working two shifts. There are considerable allied activities, involving a number of companies in neighbouring areas and beyond, providing NUOVA FRAMAR with the ideal support to ensure clients with an impeccable service from A to Z. We provide semi-finished and finished pieces with a number of surface treatments and/or machining processes in general. Our in-house mechanical construction department has a fundamental role and ensures fast routine maintenance for the more than 1,000 pieces of equipment we have in stock.

More than 50% of the turnover comes from EU countries, which allows us to consolidate a structure whose quality level is ensured by one of the world's top certification bodies. NUOVA FRAMAR is an ideal, flexible partner that can meet the highest technical/quality requirements of every product whilst ensuring an optimal price/quality ratio.

- Design

Technical, engineering and co-design studio.

The company has cutting-edge software for products and to develop custom projects. - Tool path programming

Directly from the technical department's tool path software to high-speed workstations to quickly make equipment that has no match in terms of quality. - Direction strategy

NUOVA FRAMAR provides a number of services under the most stringent control. It is no chance that there is a single contact point for every strategic role. - Mechanics

Manufacturing moulds has been the focus and starting point of every project for a number of years. High-speed workstations ensure ad-hoc moulds for our foundry. - CONSTRUCTION AND PRODUCTION

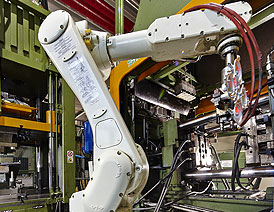

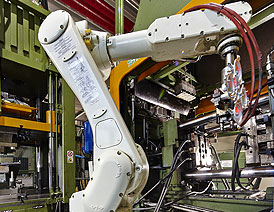

From mechanics to die-casting to actually making every product with our presses. - Automation and robotics

By ensuring production is as automated as possible, NUOVA FRAMAR is an innovative company in zamak die-casting and provides the best price/quality ratio. - Secondary machining processes

Deburring processes (with different technologies) in addition to machinery to create machining processes, provide the opportunity of having a finished product directly from our company. - metrology and logistics

Full control over the process is our long-standing philosophy Dimensional control, optical and contact CNC machines guarantee processes such as SPC, R&R. - Synergy and dynamics

Thanks to the many expert suppliers in neighbouring areas and beyond, we are a strategic partner in a network of companies, providing complementary machining processes to make finished products.

AN ALL-INCLUSIVE BUSINESS:

- PRODUCT ENGINEERING AND CO-DESIGN

- MOULD DESIGN AND MANUFACTURING

- ZAMAK DIE-CASTING

- ZAMAK VACUUM DIE-CASTING

- MECHANICAL PROCESSING

- SPECIAL FINISHES

- ASSEMBLY